Exploring Lightweight Shielded Cable Types A Comprehensive Guide

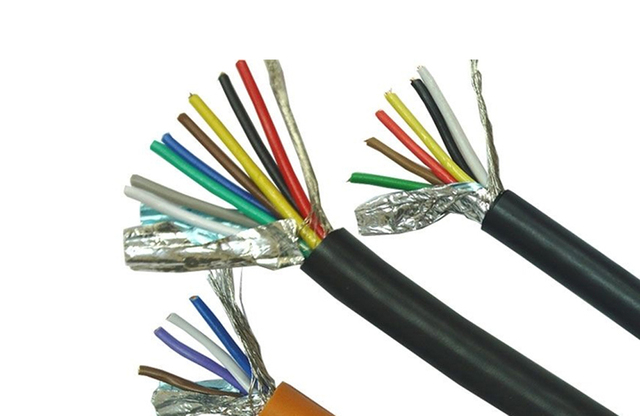

Introduction In the world of electrical engineering and telecommunications, the use of shielded cables is crucial to ensure the proper transmission of signals while minimizing interference. Shielded cables are designed to protect signals from external electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring a reliable and high-quality connection. One type of shielded cable that has gained popularity in recent years is lightweight shielded cables. These cables offer the same level of protection as traditional shielded cables but with the added benefit of reduced weight and improved flexibility. In this article, we will explore the different types of lightweight shielded cables available in the market, their applications, advantages, and key considerations for choosing the right cable for your specific needs. Types of Lightweight Shielded Cables 1. Foil Shielded Cables Foil shielded cables consist of a thin layer of aluminum or copper foil wrapped around the inner conductors. The foil acts as a barrier to block electromagnetic interference, providing excellent protection for the signals transmitted through the cable. Foil shielded cables are lightweight and flexible, making them ideal for applications where weight and space are critical factors. These cables are commonly used in data transmission, telecommunications, and audio-visual systems.  2. Braided Shielded Cables Braided shielded cables feature a woven mesh of copper or aluminum strands that surround the inner conductors. The braided shield provides a high level of protection against EMI and RFI, making these cables suitable for high-frequency applications. Braided shielded cables offer excellent flexibility and durability, making them a popular choice for industrial and automotive applications where the cable may be subjected to bending and twisting. 3. Combination Shielded Cables Combination shielded cables combine the features of foil and braided shields to provide enhanced protection against interference. Shielded cable for high-frequency applications consist of a foil shield wrapped around the inner conductors, with a braided shield surrounding the foil layer. Combination shielded cables offer superior shielding effectiveness and are commonly used in sensitive applications such as medical equipment, aerospace systems, and military communications. 4. Spiral Shielded Cables Spiral shielded cables feature a helical winding of copper or aluminum strands around the inner conductors. The spiral shield provides a good balance between flexibility and shielding effectiveness, making these cables suitable for applications that require both durability and signal integrity. Spiral shielded cables are often used in robotics, automation systems, and other industrial applications where the cable may be exposed to mechanical stress. 5. Foil-Braid-Foil Shielded Cables Foil-braid-foil shielded cables combine multiple layers of shielding to provide maximum protection against EMI and RFI. These cables typically consist of an inner foil shield, a braided shield, and an outer foil shield. The multiple layers of shielding help to minimize signal loss and ensure reliable transmission in high-noise environments. Foil-braid-foil shielded cables are commonly used in telecommunications infrastructure, data centers, and high-speed networking applications. Applications of Lightweight Shielded Cables Lightweight shielded cables find a wide range of applications across various industries due to their superior performance and durability. Some common applications of lightweight shielded cables include: 1. Aerospace and Defense: Lightweight shielded cables are used in aircraft, spacecraft, and military vehicles to ensure reliable communication and data transmission in harsh environments. 2. Automotive: Lightweight shielded cables are used in automotive systems such as engine control units, sensors, and infotainment systems to protect signals from interference and ensure optimal performance. 3. Industrial Automation: Lightweight shielded cables are essential for industrial automation systems, robotics, and machinery where reliable signal transmission is critical for safety and efficiency. 4. Medical Equipment: Lightweight shielded cables are used in medical devices and equipment to ensure accurate data transmission and patient safety. Advantages of Lightweight Shielded Cables 1. Weight Reduction: Lightweight shielded cables offer a significant weight reduction compared to traditional shielded cables, making them ideal for applications where weight is a critical factor, such as aerospace and automotive industries. 2. Flexibility: Lightweight shielded cables are more flexible than traditional shielded cables, allowing for easier installation and routing in tight spaces or complex configurations. 3. EMI and RFI Protection: Lightweight shielded cables provide excellent protection against electromagnetic interference and radio frequency interference, ensuring reliable signal transmission in noisy environments. 4. Durability: Lightweight shielded cables are designed to withstand mechanical stress, bending, and twisting without compromising signal integrity, making them suitable for rugged industrial applications. 5. Cost-Effective: Lightweight shielded cables offer a cost-effective solution for applications that require high-performance shielding while maintaining a lightweight and flexible design. Considerations for Choosing Lightweight Shielded Cables When selecting lightweight shielded cables for your specific application, there are several key considerations to keep in mind: 1. Shielding Effectiveness: Ensure that the cable provides the required level of shielding effectiveness to protect signals from interference and maintain signal integrity. 2. Signal Frequency: Consider the frequency range of the signals transmitted through the cable to choose a cable with appropriate shielding properties for optimal performance. 3. Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals, to select a cable that meets the required environmental specifications. 4. Mechanical Requirements: Consider the mechanical stress, bending radius, and flex life requirements of the application to choose a cable that can withstand the intended conditions. 5. Compliance Standards: Verify that the lightweight shielded cable complies with industry standards and regulations to ensure compatibility and reliability in your specific application. Conclusion Lightweight shielded cables offer a versatile and reliable solution for a wide range of applications that require high-performance signal transmission and protection against interference. By understanding the different types of lightweight shielded cables available, their applications, advantages, and key considerations for selection, you can make an informed decision when choosing the right cable for your specific needs. Whether you are designing a complex aerospace system, an automotive control unit, or an industrial automation solution, lightweight shielded cables can help you achieve optimal performance and reliability in your application.

2. Braided Shielded Cables Braided shielded cables feature a woven mesh of copper or aluminum strands that surround the inner conductors. The braided shield provides a high level of protection against EMI and RFI, making these cables suitable for high-frequency applications. Braided shielded cables offer excellent flexibility and durability, making them a popular choice for industrial and automotive applications where the cable may be subjected to bending and twisting. 3. Combination Shielded Cables Combination shielded cables combine the features of foil and braided shields to provide enhanced protection against interference. Shielded cable for high-frequency applications consist of a foil shield wrapped around the inner conductors, with a braided shield surrounding the foil layer. Combination shielded cables offer superior shielding effectiveness and are commonly used in sensitive applications such as medical equipment, aerospace systems, and military communications. 4. Spiral Shielded Cables Spiral shielded cables feature a helical winding of copper or aluminum strands around the inner conductors. The spiral shield provides a good balance between flexibility and shielding effectiveness, making these cables suitable for applications that require both durability and signal integrity. Spiral shielded cables are often used in robotics, automation systems, and other industrial applications where the cable may be exposed to mechanical stress. 5. Foil-Braid-Foil Shielded Cables Foil-braid-foil shielded cables combine multiple layers of shielding to provide maximum protection against EMI and RFI. These cables typically consist of an inner foil shield, a braided shield, and an outer foil shield. The multiple layers of shielding help to minimize signal loss and ensure reliable transmission in high-noise environments. Foil-braid-foil shielded cables are commonly used in telecommunications infrastructure, data centers, and high-speed networking applications. Applications of Lightweight Shielded Cables Lightweight shielded cables find a wide range of applications across various industries due to their superior performance and durability. Some common applications of lightweight shielded cables include: 1. Aerospace and Defense: Lightweight shielded cables are used in aircraft, spacecraft, and military vehicles to ensure reliable communication and data transmission in harsh environments. 2. Automotive: Lightweight shielded cables are used in automotive systems such as engine control units, sensors, and infotainment systems to protect signals from interference and ensure optimal performance. 3. Industrial Automation: Lightweight shielded cables are essential for industrial automation systems, robotics, and machinery where reliable signal transmission is critical for safety and efficiency. 4. Medical Equipment: Lightweight shielded cables are used in medical devices and equipment to ensure accurate data transmission and patient safety. Advantages of Lightweight Shielded Cables 1. Weight Reduction: Lightweight shielded cables offer a significant weight reduction compared to traditional shielded cables, making them ideal for applications where weight is a critical factor, such as aerospace and automotive industries. 2. Flexibility: Lightweight shielded cables are more flexible than traditional shielded cables, allowing for easier installation and routing in tight spaces or complex configurations. 3. EMI and RFI Protection: Lightweight shielded cables provide excellent protection against electromagnetic interference and radio frequency interference, ensuring reliable signal transmission in noisy environments. 4. Durability: Lightweight shielded cables are designed to withstand mechanical stress, bending, and twisting without compromising signal integrity, making them suitable for rugged industrial applications. 5. Cost-Effective: Lightweight shielded cables offer a cost-effective solution for applications that require high-performance shielding while maintaining a lightweight and flexible design. Considerations for Choosing Lightweight Shielded Cables When selecting lightweight shielded cables for your specific application, there are several key considerations to keep in mind: 1. Shielding Effectiveness: Ensure that the cable provides the required level of shielding effectiveness to protect signals from interference and maintain signal integrity. 2. Signal Frequency: Consider the frequency range of the signals transmitted through the cable to choose a cable with appropriate shielding properties for optimal performance. 3. Environmental Conditions: Evaluate the operating environment, including temperature, humidity, and exposure to chemicals, to select a cable that meets the required environmental specifications. 4. Mechanical Requirements: Consider the mechanical stress, bending radius, and flex life requirements of the application to choose a cable that can withstand the intended conditions. 5. Compliance Standards: Verify that the lightweight shielded cable complies with industry standards and regulations to ensure compatibility and reliability in your specific application. Conclusion Lightweight shielded cables offer a versatile and reliable solution for a wide range of applications that require high-performance signal transmission and protection against interference. By understanding the different types of lightweight shielded cables available, their applications, advantages, and key considerations for selection, you can make an informed decision when choosing the right cable for your specific needs. Whether you are designing a complex aerospace system, an automotive control unit, or an industrial automation solution, lightweight shielded cables can help you achieve optimal performance and reliability in your application.